Choosing the Right Printer Ribbon: Key Factors to Consider for Your Specific Printer Model

2024-07-22

Introduction

Selecting the right printer ribbon for your specific printer model is crucial to ensure optimal performance and print quality. Whether you are using a dot matrix printer, thermal transfer printer, or any other type of ribbon-based printer, the correct ribbon can make a significant difference in the longevity and functionality of your printing equipment. In this blog, we will explore the key factors you should consider when selecting a printer ribbon for your specific printer model.

1. Compatibility with Printer Model

Printer Make and Model

The first and foremost factor to consider is the compatibility of the ribbon with your printer’s make and model. Printer ribbons are not one-size-fits-all, and using an incompatible ribbon can lead to poor print quality and potential damage to the printer.

- Manufacturer Recommendations: Always refer to the printer manufacturer’s guidelines and recommendations for compatible ribbons. This information is typically available in the printer’s user manual or on the manufacturer’s website.

- Model-Specific Ribbons: Some printer models require specific ribbons designed exclusively for them. Ensure you purchase the ribbon that matches your printer model precisely.

2. Type of Printer Ribbon

Different types of printers require different types of ribbons. Understanding the type of ribbon your printer uses is essential.

Dot Matrix Printers

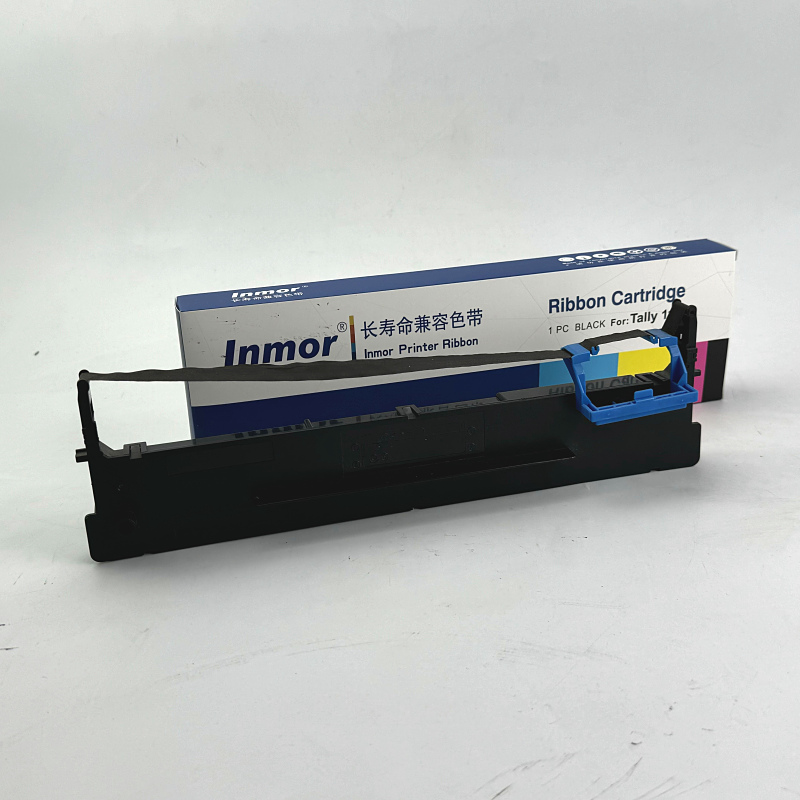

Dot matrix printers typically use fabric ribbons, which can be either cartridge-based or spool-based.

- Fabric Ribbons: These are durable and can print for a long time, making them suitable for high-volume printing environments.

- Cartridge vs. Spool: Cartridges are easier to replace, while spools may offer cost savings but require more manual handling.

Thermal Transfer Printers

Thermal transfer printers use ribbons made of wax, resin, or a combination of both.

- Wax Ribbons: Ideal for printing on paper labels and low-cost materials. They offer good print quality but are not as durable as resin ribbons.

- Resin Ribbons: Best for printing on synthetic labels and materials that require high durability and resistance to environmental factors.

- Wax-Resin Ribbons: Provide a balance between print quality and durability, suitable for a wide range of applications.

3. Print Quality Requirements

The required print quality can influence the type of ribbon you need.

- Text vs. Graphics: If your printing needs are primarily text-based, a standard ribbon may suffice. However, for high-quality graphics and barcodes, you may need a higher-quality ribbon, such as resin or wax-resin.

- Resolution: Ensure the ribbon can support the resolution capabilities of your printer. High-resolution printers require ribbons that can deliver sharp and clear prints.

4. Print Volume and Durability

Consider the volume of printing and the durability requirements of the printed material.

- High-Volume Printing: For high-volume environments, choose ribbons that offer long print runs and are cost-effective. Fabric ribbons for dot matrix printers and wax ribbons for thermal transfer printers are often preferred.

- Durability: If the printed material needs to withstand harsh conditions, such as chemicals, abrasion, or extreme temperatures, opt for resin ribbons for thermal transfer printers or high-durability fabric ribbons for dot matrix printers.

5. Environmental Conditions

The environment in which the printer operates can impact the choice of ribbon.

- Temperature and Humidity: Some ribbons perform better in specific temperature and humidity conditions. Ensure the ribbon you select can withstand the environmental conditions of your printing location.

- Exposure to Light and Chemicals: If the printed material will be exposed to direct sunlight, chemicals, or other harsh conditions, choose a ribbon designed for such environments.

6. Cost Considerations

While it is essential to select a ribbon that meets your quality and durability needs, cost is also a significant factor.

- Initial Cost vs. Long-Term Savings: While higher-quality ribbons may have a higher upfront cost, they can offer long-term savings through increased durability and fewer replacements.

- Bulk Purchasing: Consider purchasing ribbons in bulk to reduce costs if you have high-volume printing needs.

Conclusion

Selecting the right printer ribbon involves considering several critical factors, including compatibility with your printer model, the type of ribbon, print quality requirements, print volume and durability, environmental conditions, cost, and supplier reliability. By carefully evaluating these factors, you can ensure that you choose the best ribbon for your specific printer model, resulting in optimal print quality, enhanced durability, and cost-effective operations. Whether you are printing text documents, barcodes, or graphics, the right ribbon can make all the difference in achieving professional and reliable print results.